F

Fla mac

Guest

BR Bullet Making

All,

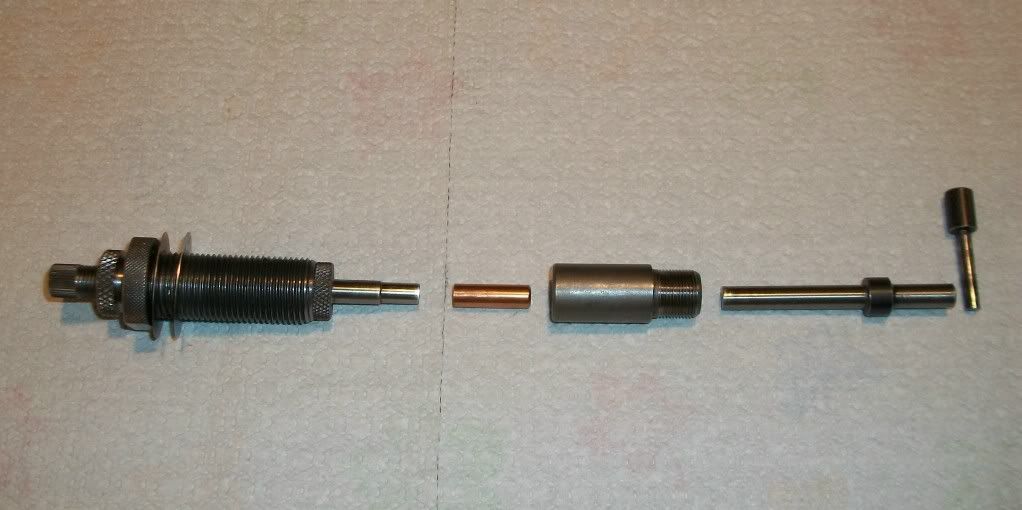

I just got started in bullet making, I have made about 1000. I have 30 cal. dies from Blackmon, I ordered two punch holders, one for core setting, and one of pointing that way I don't have a lot ot setup between the two steps.

I use a RCBS Rockcucker press. I don't think I would want to make more than about 200 bullet at one time, your arm starts to not want to work right. After I seat the cores I will point them the next day and I look inside the cored jacket to see if there is a very small amount of lead the squirets out around the punch. I also hold the punch in the jacket about 10 sec. when setting the each core, I understand the lead will continue to move after you first seat it just like when you are making cores.

I think a bullet making forum would be nice, there are two people in my club making bullets now.

John

Mims, Fl.

All,

I just got started in bullet making, I have made about 1000. I have 30 cal. dies from Blackmon, I ordered two punch holders, one for core setting, and one of pointing that way I don't have a lot ot setup between the two steps.

I use a RCBS Rockcucker press. I don't think I would want to make more than about 200 bullet at one time, your arm starts to not want to work right. After I seat the cores I will point them the next day and I look inside the cored jacket to see if there is a very small amount of lead the squirets out around the punch. I also hold the punch in the jacket about 10 sec. when setting the each core, I understand the lead will continue to move after you first seat it just like when you are making cores.

I think a bullet making forum would be nice, there are two people in my club making bullets now.

John

Mims, Fl.