G

Gerry

Guest

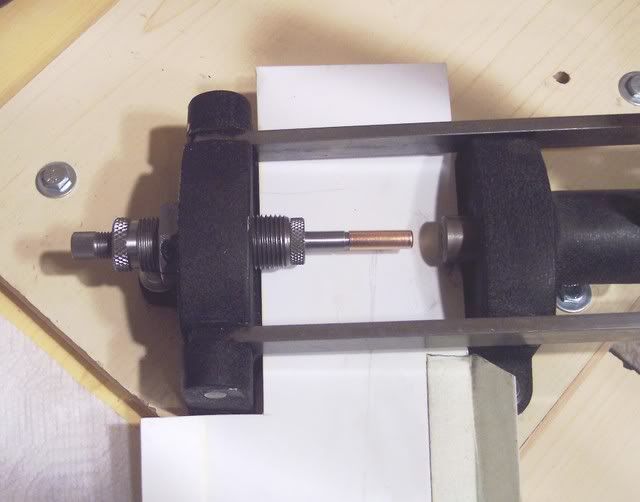

Br Bullet making

George '

Please read my post on boat tails again.

We can talk tonight if you have time.

Your correct on keeping every thing clean. My trays are clean my room is clean and my dies are clean.

As to your opinion on lubing the jackets . How would you put the jacket on the punch? {fingers} Not being a wise guy eiither]

Once you touch the lubed jacket , whats the difference?

I have found that doing this the way i do gives me great rusults. As i said before every one has their little twist.

I guess some are under the impression that i have only one makers dies also.

i'll post again 1set B&A 22 Made in Rochester at RIT thats why they are good. They were shop projects for engineering and tool and die students. They had to be good or you fluncked'

I set of Detsch 22 i use . on loan from a good friend.

3 sets of 6mm dies I upside down set by Larry blackmon. 2 sets one by detsch one by Simonson. 2 sets 30 cal by detsch.

I asked about the culver upside down sets. any one using larry blackmons upside down sets? I have used a set of homers 30s

These are backwards die in the ram.

George '

Please read my post on boat tails again.

We can talk tonight if you have time.

Your correct on keeping every thing clean. My trays are clean my room is clean and my dies are clean.

As to your opinion on lubing the jackets . How would you put the jacket on the punch? {fingers} Not being a wise guy eiither]

Once you touch the lubed jacket , whats the difference?

I have found that doing this the way i do gives me great rusults. As i said before every one has their little twist.

I guess some are under the impression that i have only one makers dies also.

i'll post again 1set B&A 22 Made in Rochester at RIT thats why they are good. They were shop projects for engineering and tool and die students. They had to be good or you fluncked'

I set of Detsch 22 i use . on loan from a good friend.

3 sets of 6mm dies I upside down set by Larry blackmon. 2 sets one by detsch one by Simonson. 2 sets 30 cal by detsch.

I asked about the culver upside down sets. any one using larry blackmons upside down sets? I have used a set of homers 30s

These are backwards die in the ram.