FBecigneul

Member

Oh,

Too much powder and too much neck tension.

Too much powder and too much neck tension.

Clean ride Al.

My on track experiences were not great. The red Cobra had the Jag rear which was originally designed for 136 horsepower and a 185 size tire, not 500 horsepower and a 315 drag radial. Carnage ensued before logic interceded.

I have never seen a drive shaft look that bad!

Mort

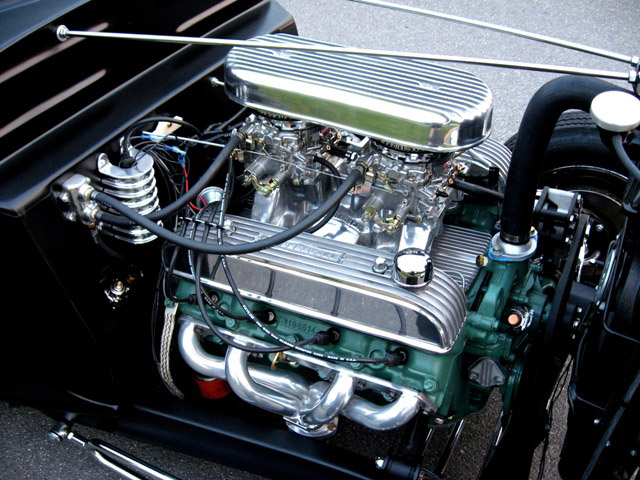

This blue Cobra was an animal of a different kind. 545 cubic inch motor that made 825 on the motor alone. Good thing the Vortech never got mounted. I have driven a few cars that were 'fast'. This car was stupid.

It's in my head from some where that the center section of a Jag (housing, ring and pinion) was 9 inch Ford. I would imagine if that were true that that much of it was tough enough? My friend Nike built a 63 Vette back in 63 and 64 that the owner wanted to retain the independ rear and they made the center from a Dana 60 and made all the rest of the parts by hand. It was tough enough to handle a hemi the made 750hp, back in the day that was a lot of power. If you have power and hook up you need good drive train. If the tires or the power are missing drive train need not be much.

My uncle had a 32 with a nailhead. Had to lengthen the frame to make it fit.Wow, Mike, you are showing your age.

Those first generation Hemi's have to be the coolest street rod engine ever, except for maybe a Buick Nail Head.

I have never admitted to being much of anything except an old Hot Rodder, my wife asked me why in the world I wanted that gosh awful monster I just had installed in the Chevelle, and the best answer I can give her is 'because".

I love modern Hot Rodding. We can all remember when all you had a choice of was reworked Factory stuff, or extremely expensive aftermarket parts. The very first set of Air Flow Reasearch Heads I ever owned was in 1977 back in my Boat Racing days. They were the old 'snow flake' Chevy aluminum castings, with the exaust side welded up, raised, and D-Ported, then angle milled 1/4 inch. In todays dollars, what I had to give for those heads would have cost $20,000.

Now, it's a matter of making a choice for the application you want. It's amazing the selection of heads, blocks, cranks, cams, induction systems, etc, that is no more than a phone call away. 496 cubic inches used to be the practical limit, now it's middle of the road. I stopped at 540 inches simply because I did not want to go to a tall block, too much hassle getting everything in the car.

We used to make street horsepower with 13 to 1 compression, big flat tappet cams, and hogged out stock heads. No idle, no vaccuum, ill tempererd, and you had to rev the darn thing untill the belts came off. Now, you can build a massive cubic inch engine, get heads that flow big numbers with maximum port velocity, Hyd Roller Cams that are computer designed to be perfectly compatible with the other parts, and you have a rather "mild" engine that will shred the tires, scare the cr-p out of you, but idle smooth, have great vacuum, run cool, and make lots of power down where you can use it.

These are great times for Hot Rodders.

My uncle had a 32 with a nailhead. Had to lengthen the frame to make it fit.