T

TCups

Guest

Head Sizing Pellets

Have been working with my brother (Jerry C.) who actually came up with the concept and is marketing (fairly successfully) the PelletGage both domestically and internationally.

After feedback from a few comments on this forum and others, Jerry did invest in a set of high quality pin gages and did find that although the tolerances of the laser cut gage holes were within specs, that the sizes labeled on the initial runs of the gases were consistently off by 0.001, probably due to the way the kerf was set up on the laser. That problem has been corrected.

I and others have looked at the rather sharp edges of the gage holes as a potential problem, and have attempted to improve its usability and reduce the tendency for the gage to shave lead on pellets larger, but very close to the size of the gage holes by polishing or chamfering the gage hole. One user used a Dremel cut off disk to dress a Dremel grinder bit to 45 deg, then, using only his fingers to turn the bit, dressed the leading edge with good results. I tried using just a felt tip, bullet shaped polishing tip with Flitz metal polish and the lowest speed on the Dremel, also with good results.

Another trick I am now using is to take the bezel off the gage and reposition it under the the plastic cover plate of the gage. This results in a few millimeters of stand-off that much more consistently align the pellet head to the gage. With a polished gage and this stand off, the "drop" of the pellet head for go/no go testing is much more reliable and reproducible for me. The downside is that turning the gage over to drop the pellet back out of the gage most often results in the skirt hanging on the elevated face plate. I find that simply using finger pressure under the pellet head and a Q-tip to guide the skirt back up and out of the gage is pretty quick and easy.

Had planned accuracy testing for .20 ga. pellets this weekend, but suffered a scope failure (Hawk Eclipse 30) on my Theoben Crusader gas ram, so I couldn't complete any conclusive testing at 30 yards (outdoors) for group size. I can say from measurments that head sizing significantly tightens the spread and consistently lowers the standard deviation of measured velocities by half or more for multiple 10-shot strings of .20 ga pellets over both a ProChronograph and a Chrony F1 (in tandem) on indoors testing. I must acknowledge that to date, I have done this only for around 100 each of .177 and .20 pellets.

As with every air rifle or powder burning rifle, we all know that specific rifles and rifle barrels have individual and sometimes peculiar preferences for specific ammo that can't easily be explained by measurement. But whether or not head sizing alone makes a significant difference in accuracy (IMO it will) has, as yet, not been established to my satisfaction by sufficient testing by me for each of my air rifles at the range.

I am however confident that:

1) There is no more accurate, more precise, or more efficient way I know of, at present, to measure pellet head size diameters for large quantities of pellets than the PelletGage,

2) There is a demonstrable and significant variation in measured head sizes of even weight-sorted, match-grade pellets, in the same lot numbers and same tins of RWS, Vogel, JSB, and Beeman pellets, and these also vary widely from the specified head size on the tin's label, for those manufactures who still or used to include that information.

3) There will be additional refinements of the gage that will further improve its performance, based on experience and customer feedback (always welcome, attention Jerry C, <pelletgage@gmail.com> )

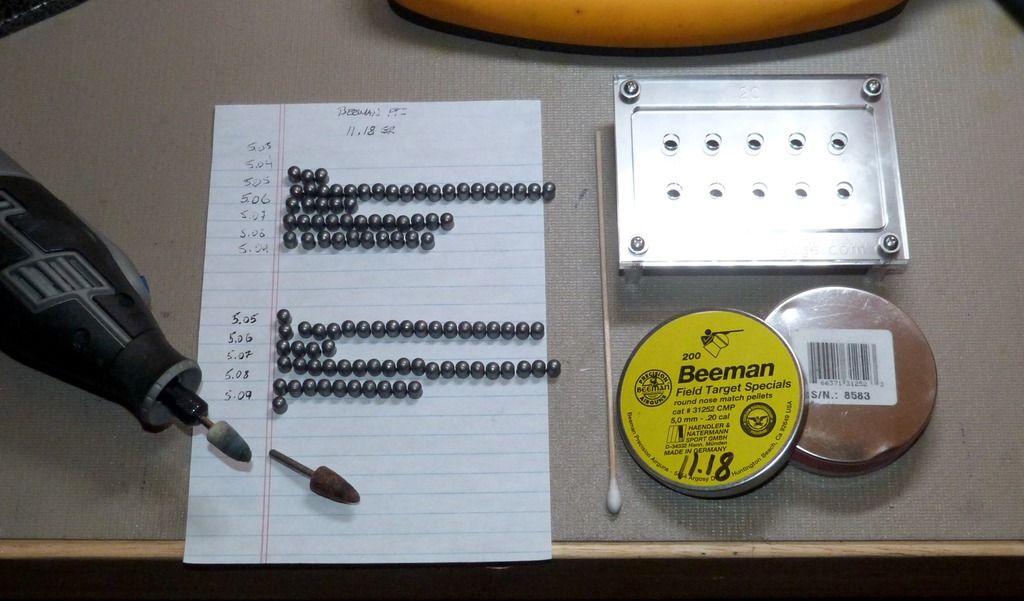

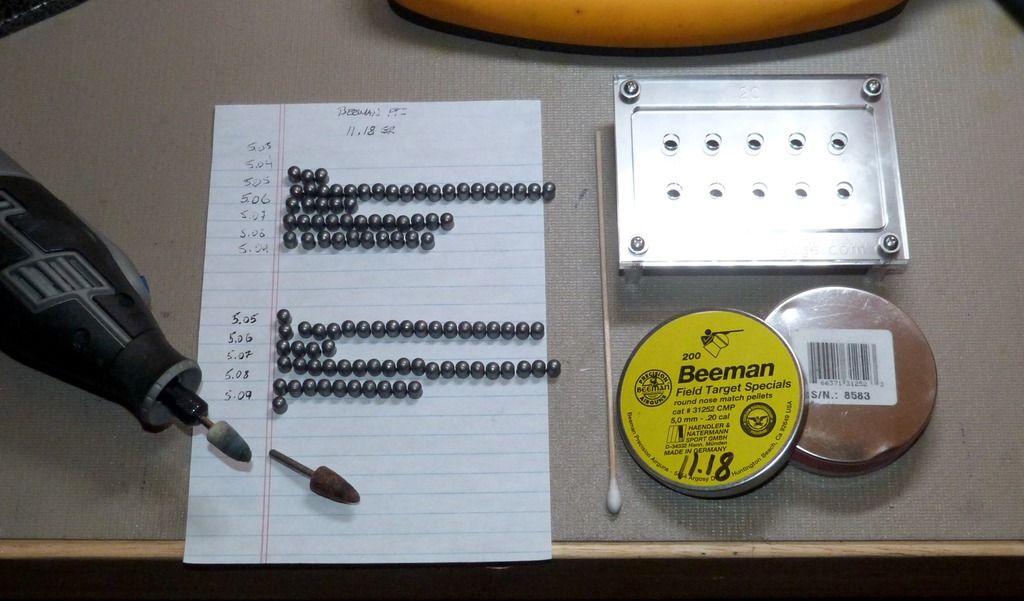

I measured head sizes on this partial tin of weighed Beeman FTS pellets (GemPro 50 digital scale) in two batches, before and after polishing the gage holes with Flitz and a felt-tip bit on a Dremel tool. I wanted to make sure that a burr on the 5.07 mm gage hole wasn't responsible for the bimodal distribution of head sizes. It wasn't.

. . . and Michael, regarding your comment:

"The author of the blog was able to draw a definitive conclusion about pellet head size and impact on accuracy in just three groups.... probably shot outdoors from a turd rifle that hadn't been cleaned in a 'coons age.

Keep an eye on this guy. Amazing work.....and a fabulous example of controlled scientific procedure...."

First, I readily acknowledge that, on this forum, I am on the home turf of bench rest air rifle enthusiasts, and though an outsider to that clique, I know enough to appreciate the extremes of time, money and quality equipment needed to be competitive in the world of bench rest shooters. I also know enough to occasionally come here to read what those who are more experienced and accomplished than I can teach me, usually just by lurking. . . . but really? That's a pretty elitist comment even from a bench rest shooter.

Would it be, perhaps more equitable to just say that he formed an opinion based on very limited information, and shared it? All of us would do well, of course, to take anything we read (or post?) on line with "a grain of salt", I have surely posted my share of inaccurate information and flawed opinions on line.

Amongst the "great unwashed" -- those who are also air rifle enthusiasts, including a few fledgling field trial shooters, like my brother Jerry, there are those who, yes, still occasionally shoot "turd" rifles costing a few hundred rather than a few thousand (not counting rests, bags and accessories), who usually shoot them outdoors, who still enjoy it, and who still strive to figure out how to improve their skills and results within limited budgets. It doesn't always make their opinions wrong or their efforts unworthy. You could simply disagree (and say so) without that sort of derisive-toned mocking. I suspect you aren't really that type of person off line. If you were to meet up with the author of that blog at an air gun event (I have), then I bet you would find him to be a nice enough sort as well.

Have been working with my brother (Jerry C.) who actually came up with the concept and is marketing (fairly successfully) the PelletGage both domestically and internationally.

After feedback from a few comments on this forum and others, Jerry did invest in a set of high quality pin gages and did find that although the tolerances of the laser cut gage holes were within specs, that the sizes labeled on the initial runs of the gases were consistently off by 0.001, probably due to the way the kerf was set up on the laser. That problem has been corrected.

I and others have looked at the rather sharp edges of the gage holes as a potential problem, and have attempted to improve its usability and reduce the tendency for the gage to shave lead on pellets larger, but very close to the size of the gage holes by polishing or chamfering the gage hole. One user used a Dremel cut off disk to dress a Dremel grinder bit to 45 deg, then, using only his fingers to turn the bit, dressed the leading edge with good results. I tried using just a felt tip, bullet shaped polishing tip with Flitz metal polish and the lowest speed on the Dremel, also with good results.

Another trick I am now using is to take the bezel off the gage and reposition it under the the plastic cover plate of the gage. This results in a few millimeters of stand-off that much more consistently align the pellet head to the gage. With a polished gage and this stand off, the "drop" of the pellet head for go/no go testing is much more reliable and reproducible for me. The downside is that turning the gage over to drop the pellet back out of the gage most often results in the skirt hanging on the elevated face plate. I find that simply using finger pressure under the pellet head and a Q-tip to guide the skirt back up and out of the gage is pretty quick and easy.

Had planned accuracy testing for .20 ga. pellets this weekend, but suffered a scope failure (Hawk Eclipse 30) on my Theoben Crusader gas ram, so I couldn't complete any conclusive testing at 30 yards (outdoors) for group size. I can say from measurments that head sizing significantly tightens the spread and consistently lowers the standard deviation of measured velocities by half or more for multiple 10-shot strings of .20 ga pellets over both a ProChronograph and a Chrony F1 (in tandem) on indoors testing. I must acknowledge that to date, I have done this only for around 100 each of .177 and .20 pellets.

As with every air rifle or powder burning rifle, we all know that specific rifles and rifle barrels have individual and sometimes peculiar preferences for specific ammo that can't easily be explained by measurement. But whether or not head sizing alone makes a significant difference in accuracy (IMO it will) has, as yet, not been established to my satisfaction by sufficient testing by me for each of my air rifles at the range.

I am however confident that:

1) There is no more accurate, more precise, or more efficient way I know of, at present, to measure pellet head size diameters for large quantities of pellets than the PelletGage,

2) There is a demonstrable and significant variation in measured head sizes of even weight-sorted, match-grade pellets, in the same lot numbers and same tins of RWS, Vogel, JSB, and Beeman pellets, and these also vary widely from the specified head size on the tin's label, for those manufactures who still or used to include that information.

3) There will be additional refinements of the gage that will further improve its performance, based on experience and customer feedback (always welcome, attention Jerry C, <pelletgage@gmail.com> )

I measured head sizes on this partial tin of weighed Beeman FTS pellets (GemPro 50 digital scale) in two batches, before and after polishing the gage holes with Flitz and a felt-tip bit on a Dremel tool. I wanted to make sure that a burr on the 5.07 mm gage hole wasn't responsible for the bimodal distribution of head sizes. It wasn't.

. . . and Michael, regarding your comment:

"The author of the blog was able to draw a definitive conclusion about pellet head size and impact on accuracy in just three groups.... probably shot outdoors from a turd rifle that hadn't been cleaned in a 'coons age.

Keep an eye on this guy. Amazing work.....and a fabulous example of controlled scientific procedure...."

First, I readily acknowledge that, on this forum, I am on the home turf of bench rest air rifle enthusiasts, and though an outsider to that clique, I know enough to appreciate the extremes of time, money and quality equipment needed to be competitive in the world of bench rest shooters. I also know enough to occasionally come here to read what those who are more experienced and accomplished than I can teach me, usually just by lurking. . . . but really? That's a pretty elitist comment even from a bench rest shooter.

Would it be, perhaps more equitable to just say that he formed an opinion based on very limited information, and shared it? All of us would do well, of course, to take anything we read (or post?) on line with "a grain of salt", I have surely posted my share of inaccurate information and flawed opinions on line.

Amongst the "great unwashed" -- those who are also air rifle enthusiasts, including a few fledgling field trial shooters, like my brother Jerry, there are those who, yes, still occasionally shoot "turd" rifles costing a few hundred rather than a few thousand (not counting rests, bags and accessories), who usually shoot them outdoors, who still enjoy it, and who still strive to figure out how to improve their skills and results within limited budgets. It doesn't always make their opinions wrong or their efforts unworthy. You could simply disagree (and say so) without that sort of derisive-toned mocking. I suspect you aren't really that type of person off line. If you were to meet up with the author of that blog at an air gun event (I have), then I bet you would find him to be a nice enough sort as well.

Last edited by a moderator: