B

bigngreen

Guest

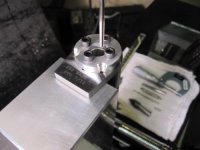

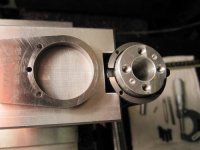

I need some feed back on this, what I have is a Savage long action on a PTG mandrel with ground tapered bushings. I have a dead center in the 4-jaw on one end and a live center in the tail stock, I adjusted the chuck and tail stock till I had zero run out on the mandrel on both ends then checked the face of the action and had .0013 of run out. Is my method sound or is it all jacked up?