Z

zfastmalibu

Guest

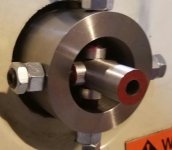

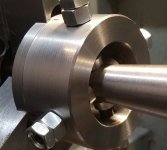

Anything more than 4 screws will just eat up time dialing in the barrel. I use 1/2-20 set screws with brass inserts, flat. In a perfect world the screws would have feet that pivoted on a ball but that adds too much length to the screws. I've made several spiders out of backing plates for chucks but that leaves the screws exposed and sooner or later they will bite you. My fingers have sounded like a playing card in bicycle spokes. One time my arm was doing 1250 RPMs and I tore the sleeves out of a sweater and long sleeve shirt getting away from the damn thing. Just stupidity on my part. Make a full diameter spider where you can have the set screws at or below the surface of the OD. You may end up with two sets of screws, different lengths.

I like how you think.

https://www.youtube.com/watch?v=oDWz2Ffn2Po