JonathanK

New member

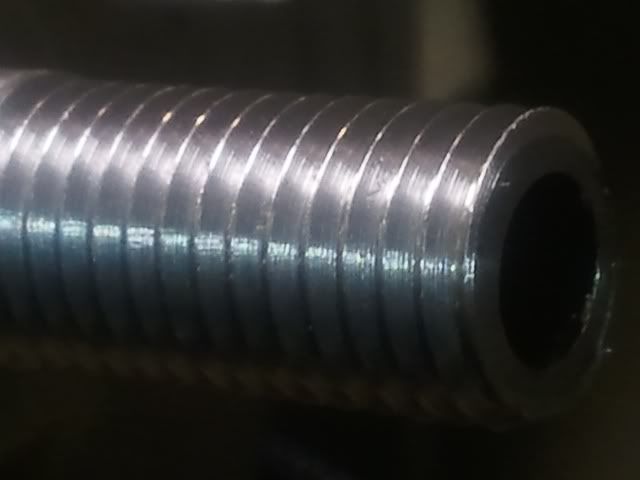

I recently purchased a Nikcole mini-grooving holder with a TIN carbide 60 degree threading insert. I really like this type of setup but I am getting chatter, I normally set my compound to 29.5 degrees going in with the compound and use the cross-slide to back out where I want to end my threads. I run the spindle at 65rpm. I have tried moving the compound, different rake and different heights of the tool. I have also tried going in with the cross slide. I havent tried different spindle speeds yet as Im still learning and not quite ready to thread faster. Im thinking it may just be that my pm1236 isnt quite heavy enough to thread this slow with carbide. When I change back to HSS it cuts nice and clean. Also does anyone know where I can find hss inserts for the mini-grooving holder?