You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rimfire Firing Pin Testing

- Thread starter mrh1958

- Start date

C

cobra1

Guest

A tad technical.

Lets start with the fundamentals of how/why the primer ignite's.

gn

Lets start with the fundamentals of how/why the primer ignite's.

gn

If I'm not mistaken the thought stems from a basic principle of metallurgy. The thought is that when one understands the steps of how a case is formed, the rather sharp radius that forms the rim is subject to work hardening and a greater variable of how much work hardening. As such, better consistancy is reached by avoiding that radius. This has been my understanding of the issue.

C

cobra1

Guest

If I'm not mistaken the thought stems from a basic principle of metallurgy. The thought is that when one understands the steps of how a case is formed, the rather sharp radius that forms the rim is subject to work hardening and a greater variable of how much work hardening. As such, better consistancy is reached by avoiding that radius. This has been my understanding of the issue.

Additionally, at the radius bounded by the thickness of the brass, it is solid brass with no HE material there; so why waste kinetic energy pounding on an empty rock.

gn

Additionally, at the radius bounded by the thickness of the brass, it is solid brass with no HE material there; so why waste kinetic energy pounding on an empty rock.

gn

That makes sense....thanks

If I'm not mistaken the thought stems from a basic principle of metallurgy. The thought is that when one understands the steps of how a case is formed, the rather sharp radius that forms the rim is subject to work hardening and a greater variable of how much work hardening. As such, better consistancy is reached by avoiding that radius. This has been my understanding of the issue.

I agree ......should be at least some less spread in velocity in good ammo or one would think so

glynn angle

Member

The great one

Only "the Great One" really knows about such things. You must be a member of his POSSE to ask questions on his website. If you go over there, walk very softly or you'll be goonnneeee

Only "the Great One" really knows about such things. You must be a member of his POSSE to ask questions on his website. If you go over there, walk very softly or you'll be goonnneeee

Black Talon

New member

C

cobra1

Guest

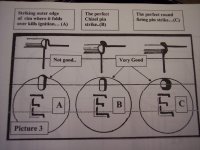

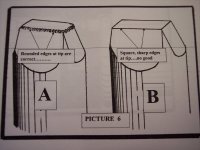

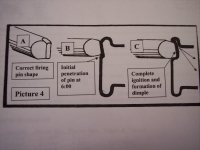

I don't remember where these drawings came from, but I've had them on my HDD for a while:

View attachment 19588

View attachment 19589

View attachment 19590

I was hoping to get into the physics of ignition; but no luck. These diagrams are good and accurately describe the geometry. No need to compress brass on brass and waste energy. All energy needs to be surgically aimed at collapsing the walls of the shell into the primer material.

What is needed is to hit the brass with enough kinetic energy where is collapses rapidly into the primer material such that it rapidly compresses it such that the strain rate is high and uniform enough to raise the temperature above the combustion temp and Kaboom, a DETONATION!

If your old enough, it was just like you were a kid hitting a "roll" of cap gun caps with a hammer.

g