P

piniongear

Guest

I have installed a Jewell trigger on a Model 70 and have a problem.

The trigger works and the bolt cocks but my problem is the safety does not engage.

I have installed a Jewell on a Winnie before and remember having the same problem.

To make the safety work on that rifle I had to disassemble the bolt and then found the 'butcher' I bought the rifle from had done some 'home gunsmithing' using a dremel tool to install a Jewell (which he removed before selling me the gun) and it was a mess. He sold me the gun saying the safety did not work, which was very true!

Pic of that mess......

I just bought a Tubb firing pin and a new cocking piece to install on that rifle.

The safety was made workable by carefully machining a half notch in the cocking piece for the safety lever to engage in.

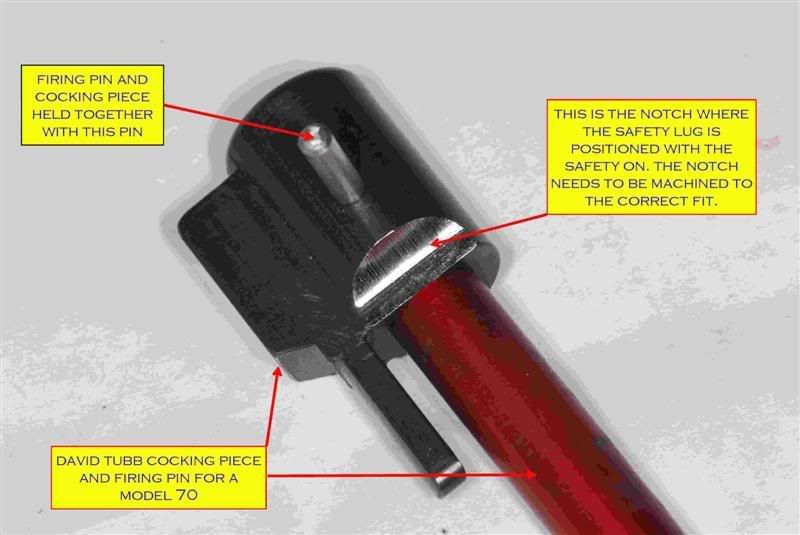

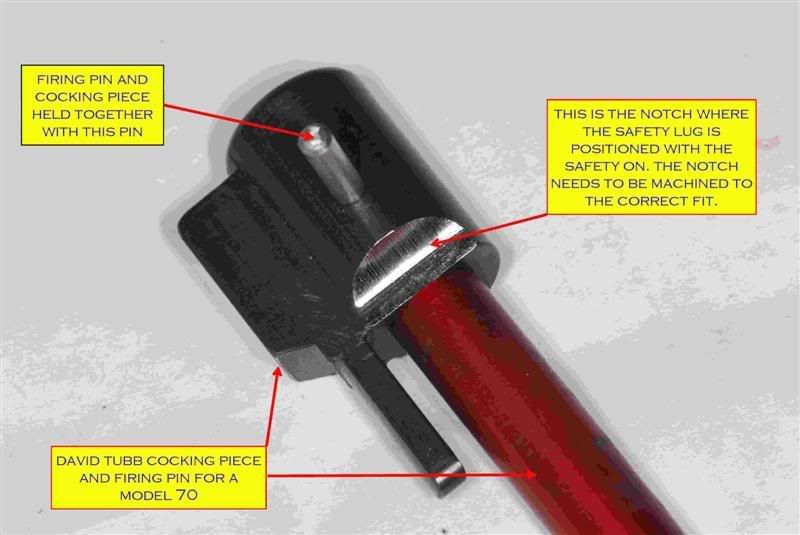

Here is a pic of the notch on the replacement cocking piece.....

But I have forgotten the details of how I did it.

Can anyone jog my failing memory as to what I need to do?

Thank you......pg

The trigger works and the bolt cocks but my problem is the safety does not engage.

I have installed a Jewell on a Winnie before and remember having the same problem.

To make the safety work on that rifle I had to disassemble the bolt and then found the 'butcher' I bought the rifle from had done some 'home gunsmithing' using a dremel tool to install a Jewell (which he removed before selling me the gun) and it was a mess. He sold me the gun saying the safety did not work, which was very true!

Pic of that mess......

I just bought a Tubb firing pin and a new cocking piece to install on that rifle.

The safety was made workable by carefully machining a half notch in the cocking piece for the safety lever to engage in.

Here is a pic of the notch on the replacement cocking piece.....

But I have forgotten the details of how I did it.

Can anyone jog my failing memory as to what I need to do?

Thank you......pg