I was weighing up options awhile back for a floating reamer holder, knowing my preference was for something with both lateral & axial float. After looking at the commercially available options & cost etcwas possibly always going to make one myself. Was tempted to work from my own design, however had done alot of reinventing the wheel around that time & just wanted to get it done, so instead purchased one of the "Hemingway" designs & kits.

Did take some liberties, opting to TIG weld instead of loctiting the arbour assembly, then finish machine its outside thread.

So far it was worked flawlessly following a pre-bored hole & delivered a min spec chamber everytime.

I know some will preach the evils about using a floating holder @ all, and instead using a fixed reamer in absolute alignment with the spindle axis, however i feel to my mind i'm well justified in having gone the route i did.

My lathe a (Colchester mascot) chalked up 50 years a while back, is in daily use for a eclectic mix of general machining jobs & has some slight wear, and our workshop definitely isn't climate controlled i.e ranging from 50 degrees to -9.

I'd dearly love to have some wizzbang machine solely for gunsmithing, however it just won't happen, so i as the operator use all my skill and guile to mitigate those factors that contribute to inaccuracy and get the best results from my venerable old machine. Also to purchase a new machine of equivalent build quality to my existing lathe, isnt one that you recoup the cost of doing barrel work in a short time.

A few of my other "homemade" barrel work fixtures/items:

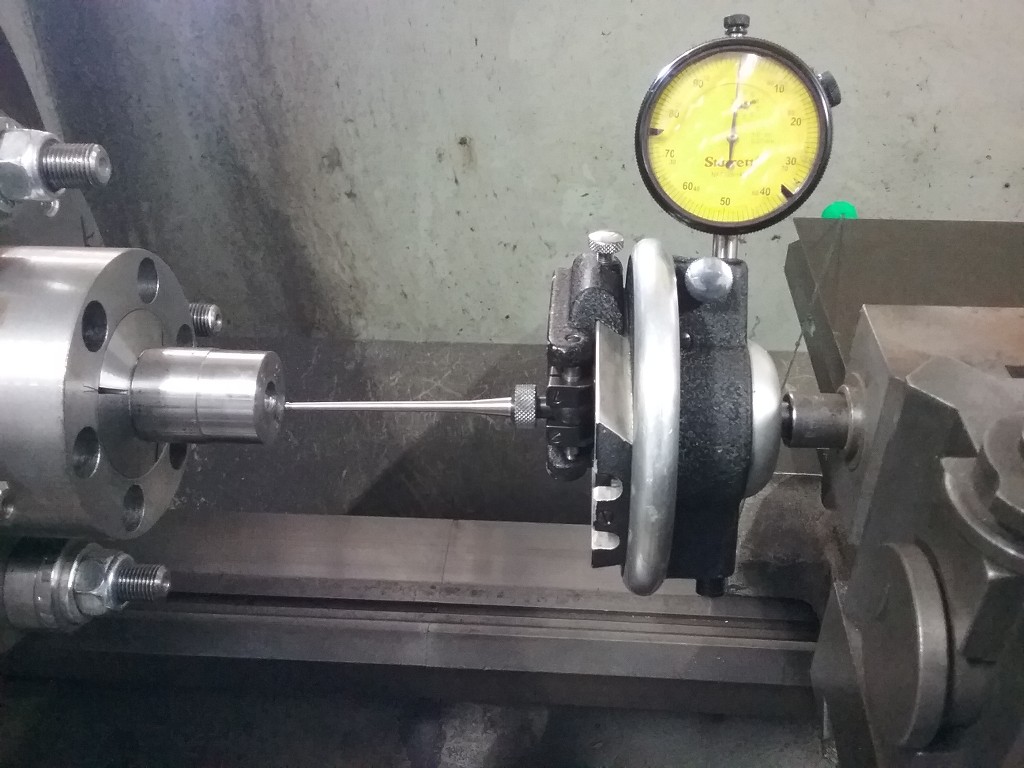

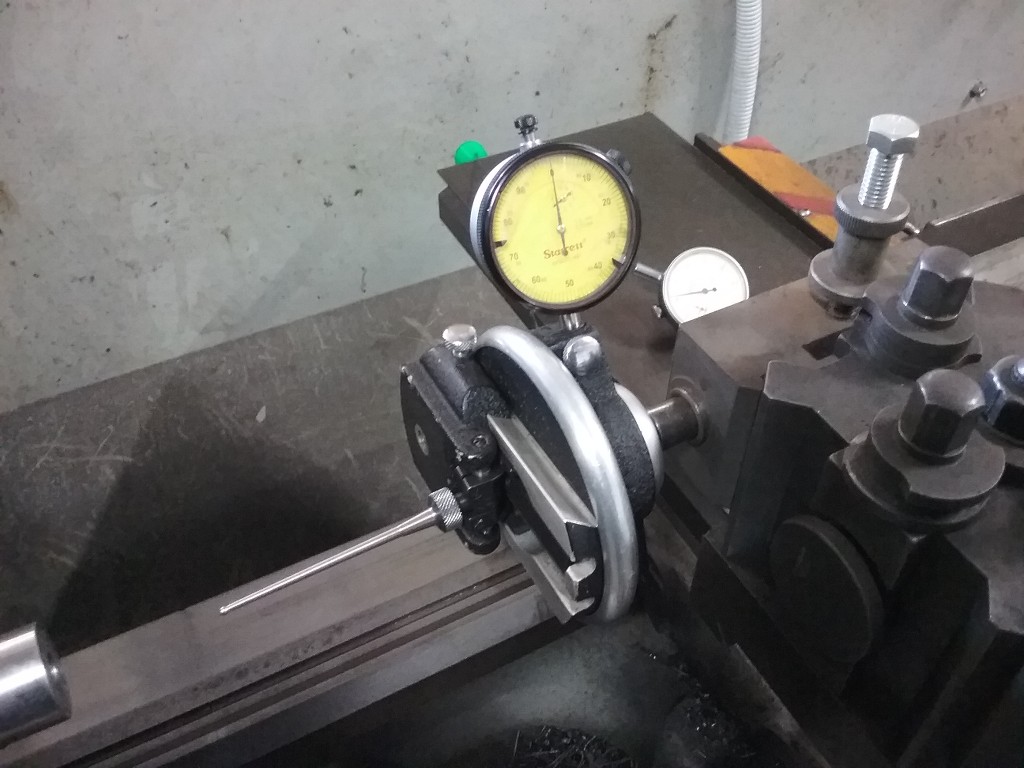

A slender contact point for my centricator, that allows me to reach 3" in & get either side of the throat & leade for most chamberings. Obviously a longer point, desensitises the inherent resolution all i do to counter this is swap in progressively finer dial indicators, i.e .01mm now reads as .001" resolution and then i change to a .0001" clock for my final setup.

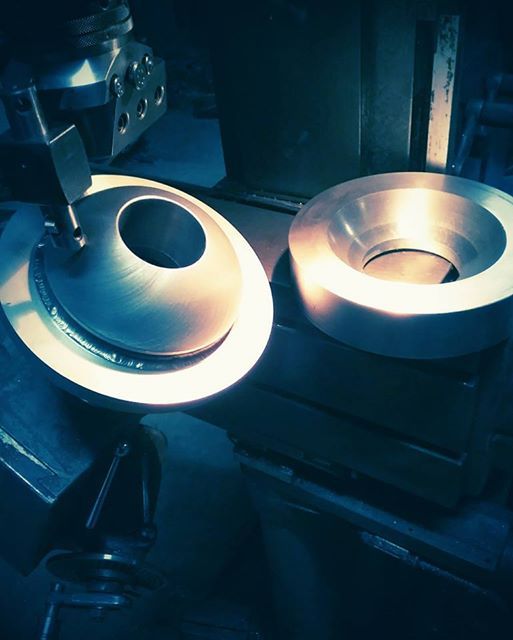

And also this is my finely adjustable gimballing collet fixture, the collet nose can be changed out & i fit a universal action attachment in its place for truing work, for non cylindrical actions.