I have noticed a recent change in how the barrel sits in the barrel channel, plus when the action screws are torqued I get bolt binding when moving fore/aft.

The details on the stock (not sure if I am supposed to omit the mfg)

F-class stock

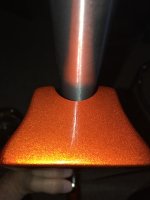

Bedded with Marine Tex (barrel centered in the channel with wraps of electrical tape)

Painted with good quality auto paint and clear coat

Action screws torqued to 40 in/lbs as measured with a Borka ATK and Wheeler digital FAT wrench

BVSS action with a 1" straight taper bull barrel

I took the action out yesterday and did a visual inspection on the bedding. I can't see anything that would cause the action to sit skewed in the stock. The bedding is not cracked or visibly malformed, and no foreign objects or materials were found. The barrel was floated enough that a dollar bill would easily pass the entire length of the barrel channel. Now, when torqued to 40 in/lbs, the barrel makes contact with the stock and the bill won't pass.

Additionally, when the rear action screw is torqued to spec the bolt binds in it's fore/aft travel. I tested this with torque values ranging from 15-40 in/lbs in 5 in/lb increments. At 35 in/lbs, the bolt moved freely. At 40 it was bindung up. Even at 38 it would move ok, but by 40 it was sticking. This leads me to believe there is a high point somewhere that when the action screws are torqued causes the action to flex enough to cause the binding. The high point, I'm guessing is the contact point of the barrel and the stock.

This condition is new. I've only had the stock a short time, and it's only been out to the range I think 4 times. I've always torqued to 40 in/lbs and the binding was never an issue.

I put this barreled action into a factory Savage F-class stock and when torqued to 40 in/lbs the barrel sits straight in the barrel channel, and the bolt moves freely. This leads me to think the stock has an issue but I don't know what else I can do to diagnose and resolve the issue.

Any input on this situation would be greatly appreciated. I can post pics if that would help.

The details on the stock (not sure if I am supposed to omit the mfg)

F-class stock

Bedded with Marine Tex (barrel centered in the channel with wraps of electrical tape)

Painted with good quality auto paint and clear coat

Action screws torqued to 40 in/lbs as measured with a Borka ATK and Wheeler digital FAT wrench

BVSS action with a 1" straight taper bull barrel

I took the action out yesterday and did a visual inspection on the bedding. I can't see anything that would cause the action to sit skewed in the stock. The bedding is not cracked or visibly malformed, and no foreign objects or materials were found. The barrel was floated enough that a dollar bill would easily pass the entire length of the barrel channel. Now, when torqued to 40 in/lbs, the barrel makes contact with the stock and the bill won't pass.

Additionally, when the rear action screw is torqued to spec the bolt binds in it's fore/aft travel. I tested this with torque values ranging from 15-40 in/lbs in 5 in/lb increments. At 35 in/lbs, the bolt moved freely. At 40 it was bindung up. Even at 38 it would move ok, but by 40 it was sticking. This leads me to believe there is a high point somewhere that when the action screws are torqued causes the action to flex enough to cause the binding. The high point, I'm guessing is the contact point of the barrel and the stock.

This condition is new. I've only had the stock a short time, and it's only been out to the range I think 4 times. I've always torqued to 40 in/lbs and the binding was never an issue.

I put this barreled action into a factory Savage F-class stock and when torqued to 40 in/lbs the barrel sits straight in the barrel channel, and the bolt moves freely. This leads me to think the stock has an issue but I don't know what else I can do to diagnose and resolve the issue.

Any input on this situation would be greatly appreciated. I can post pics if that would help.