T

TRA

Guest

Al,

'splain why ?

why can't you torque in place and then true ?

i am a big believer in torque wrenches for repeatability.

If you have a precision fit torquing it may, "MAY" register itself back in line. When you assemble two parts foreign to each other and torque them they will create a fitup that they may repeat. But, unless they are of close tolerance each part torqued together will not take the same set.

Carbide has speed limits just as HSS does, it's just a higher sfpm, but you can over do the speed and burn the edge off of carbide. The biggest mistake most do when they use carbide is to spin the work too fast and not increase the feed and depth of cut. Carbide's sweet spot is .030-.050 finish dept with quality steel in lathe work.Quote Originally Posted by CMaier View Post

i was under the impression the carbide wants high speed not slow speed.

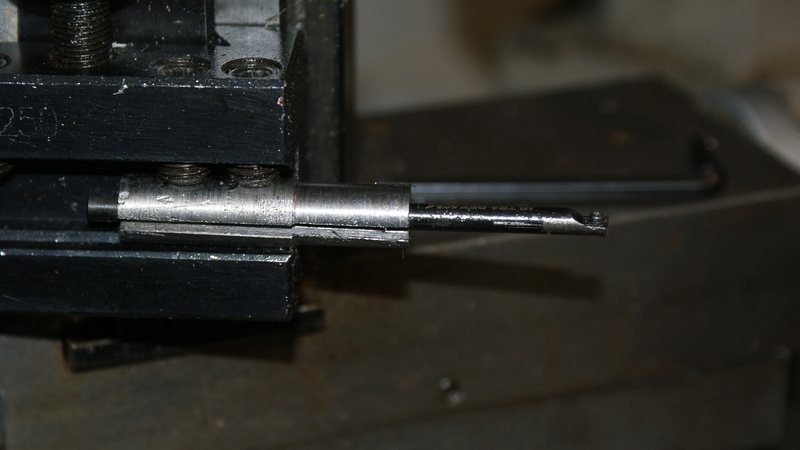

i use a micro100 long small bar ...i try to turn the speed up when using it.

???