Well, thought I'd include a few more updates of this bugger.

Disclaimer: Photobucket for the most part SUCKS IMO. . . Half the time when I resize photos it doesn't work for some reason. Never used to be this way. I don't get it. . .

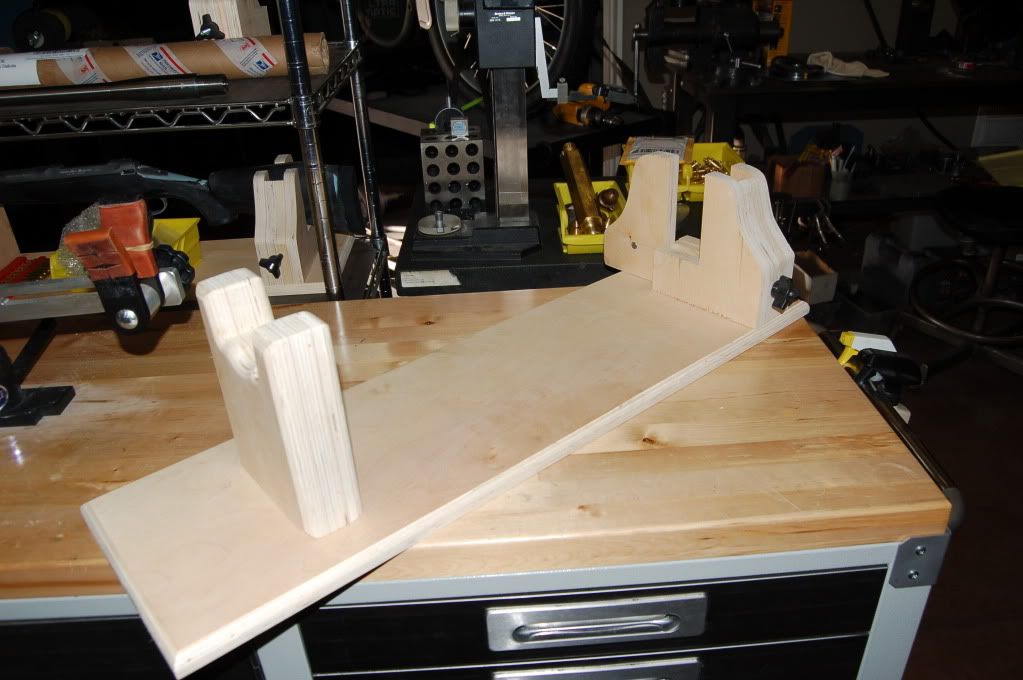

This rifle is now completed. The customer wants to apply the finish himself. So, here's a medley of photos showing the finished work and some processes. They aren't in any particular order.

You'll notice many pics of the trigger guard. I went through about ten of these damn things to get what I wanted. I made some "bold" decisions on this rifle. Being with the US Team in 2003 taught me a few things. Like benchrest, a prone shooter hopes/looks for a particular condition that he/she finds favorable. When it does it's to their interest to sling as many rounds down range as the guys in the pits can keep up with. That being the theme I wanted my customer to be able to manipulate the bolt, clear the fired round, load and fire without having to break position. This required opening up the loading port a bit and moving the entire action towards the rear. The trigger shoe on the Barnard is able to be located in different positions so moving the action to the rear didn't hurt this. What it did do however was complicate the trigger guard. The standard Sunny Hill that I'd normally use wasn't going to work since the back half would have been buried in the pistol grip by a ridiculous amount.

So I turned (once again) to the Swiss boys at Grunig/Elmiger for guidance and ideas. Specifically, the G/E FT300 CISM rifle that I used to service once upon a time. Years ago I built a 6X47 Swiss Match NRA Match rifle for a guy. The trigger guard on that gun also emulates the G/E FT300.

By and large I like the way it came out. I went through several revisions getting it to look like something. Finally resorting to grinding a contour on a carbide endmill to make a form tool to get the radius I wanted on the bow and tongue. When it was just flat it looked "8th grade shop class" if you know what I mean.

The cheek hardware is also my stuff. Machined from aluminum with brass bushing inserts pressed in, finish machined and then honed to fit the pins. This design is like the Warner Tool Company version (I'll never be guilty of having an original thought) where the jack screw stays in the piece so that the height setting is retained when the cheek piece is removed to pull the bolt. (per the international rules as this is a "safe gun". Al Warner is a sharp ol cat. I always learn something when looking at his stuff and try to emulate it.

And yes, that is a recoil lug on the front of this thing. I know Barnards don't use this. I made my own. (actually my girlfriend helped design it as I've been "learnin" her on the software.) Years ago (2002/2003) when the CG Millenium action came out I had the experience of dealing with an action that didn't use the conventional lug system. That rifle was a horrible experience that cost a very good friend of mine a great deal of money and frustration. A well respected smith built it and it wouldn't hold 3" groups at 200 yards. It was minute of 8 ring at 1000. I slaved over that damn gun and in the end he sold the B/A and gave me the stock.

SO I put lugs on these types now. I know it may not be needed but its certainly not hurting anything either. That's my story and I'm sticking to it.

Again, sorry about some of the pics being so big. If nothing else you can see all the little details this way. Keeps me honest!

All the best,

Chad

C