You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

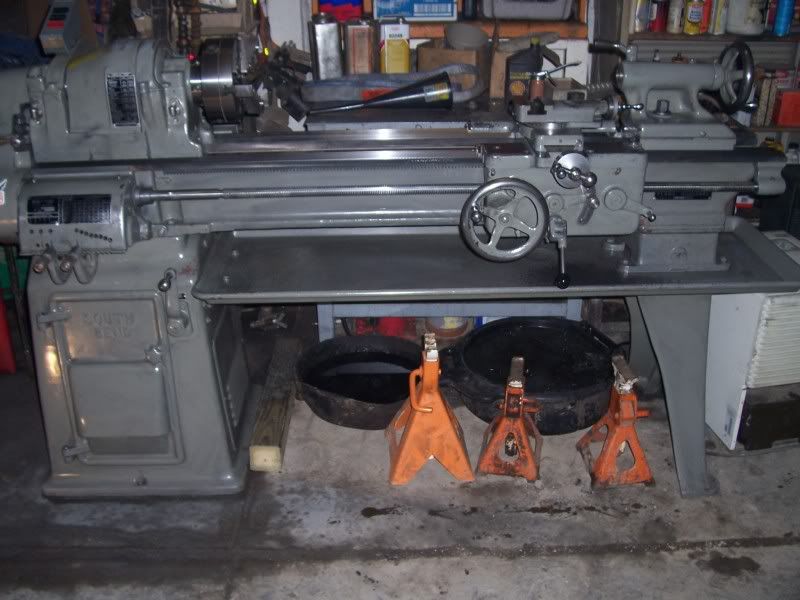

13" South Bend

- Thread starter eddief

- Start date

Had one just like it except under the Clausing nametag. Sold it for $1,000 and felt fortunate to get that much for it as it was pretty much used up. A couple of things I wish it had was a little slower speed for threading, a little more horsepower (better phase converter), and a better toolholder (which is correctable) if I remember correctly. Otherwise, a pretty good lathe.

JerrySharrett

Senile Member

South Bend and Clausing are not the same lathe for many reasons.

Looking at the photos the lathe is pristine or the ways have been reground.

As a gunsmith lathe, the 13" SBL headstock, IMO, is too long for barrel word through the headstock. Some have developed suitable, to them, methods to get around this. Many good benchrest barrel chambering jobs have been done by methods other than through the headstock though.

As a general purpose lathe this is a good lathe and should bring $2,500-$4,000 if it also had a 4-jaw chuck.

Looking at the photos the lathe is pristine or the ways have been reground.

As a gunsmith lathe, the 13" SBL headstock, IMO, is too long for barrel word through the headstock. Some have developed suitable, to them, methods to get around this. Many good benchrest barrel chambering jobs have been done by methods other than through the headstock though.

As a general purpose lathe this is a good lathe and should bring $2,500-$4,000 if it also had a 4-jaw chuck.

M.D.Spencer

New member

Clausing???

Clausing were made in Kalamazoo, MI.

"I copied from http://www.lathes.co.uk/clausing/page11.html"

PAUL AND OTTO CLAUSING

My father Paul and uncle Otto Clausing were born near the end of the 19th century and grew up on a small farm in very rural Hardin County, Iowa. Otto was three years older than Paul, and showed early evidence of a strong natural mechanical skill. Their parents had a tabletop "grandfather's clock"; in other words a clock with a pendulum. At approximately 11 years of age Otto would take this clock apart when the parents were away. Many children could have done that. The impressive aspect was that Otto would have it back together again before the parents returned. It would be working perfectly, and the parents did not know that Otto had been practicing his mechanical skills.

Time went by. By the early 1920s Otto was a carpenter and lead house builder building expensive homes in Kansas City. Paul was a commercial artist doing artwork for the Monarch Film Company. Paul started working for Monarch in Osage, Iowa. At the time that Paul and Hilda were married (Christmas 1925) the Monarch Company moved to Waterloo, Iowa. Then in 1929 Monarch moved to Kansas City, Missouri. Paul and Otto were back together.

Paul bought a South Bend lathe and put it in the basement, and used it as a hobby machine. After a while he started to think that he could make a better lathe. Then in the Fall of 1929 the stock market crashed, and the great depression started, even so, by 1931 Paul decided that he should get into the lathe business. He was motivated by three factors:

1.

He could make a better lathe than South Bend

2.

He thought that the Monarch Film Company did not have a bright future

3.

He wanted to be his own boss

I love your lathe. Are you going to sell it?

Mark

Clausing were made in Kalamazoo, MI.

"I copied from http://www.lathes.co.uk/clausing/page11.html"

PAUL AND OTTO CLAUSING

My father Paul and uncle Otto Clausing were born near the end of the 19th century and grew up on a small farm in very rural Hardin County, Iowa. Otto was three years older than Paul, and showed early evidence of a strong natural mechanical skill. Their parents had a tabletop "grandfather's clock"; in other words a clock with a pendulum. At approximately 11 years of age Otto would take this clock apart when the parents were away. Many children could have done that. The impressive aspect was that Otto would have it back together again before the parents returned. It would be working perfectly, and the parents did not know that Otto had been practicing his mechanical skills.

Time went by. By the early 1920s Otto was a carpenter and lead house builder building expensive homes in Kansas City. Paul was a commercial artist doing artwork for the Monarch Film Company. Paul started working for Monarch in Osage, Iowa. At the time that Paul and Hilda were married (Christmas 1925) the Monarch Company moved to Waterloo, Iowa. Then in 1929 Monarch moved to Kansas City, Missouri. Paul and Otto were back together.

Paul bought a South Bend lathe and put it in the basement, and used it as a hobby machine. After a while he started to think that he could make a better lathe. Then in the Fall of 1929 the stock market crashed, and the great depression started, even so, by 1931 Paul decided that he should get into the lathe business. He was motivated by three factors:

1.

He could make a better lathe than South Bend

2.

He thought that the Monarch Film Company did not have a bright future

3.

He wanted to be his own boss

I love your lathe. Are you going to sell it?

Mark

S

ShadowChaser

Guest

I have a 13" Southbend very similar to the one in your photographs. Mine was made in 1978 and was in nearly new condition when I purchased it. I've had a number of bigger and fancier lathes over the years, American Pacemaker, Victor, Mauser, Axelson, Hendy, Le Blond, and Cincinnati Tray top to mention a few.

Of all these lathes, the Southbend is the least suited for production work due to its low power and inefficient power transmission method being a flat belt driving the spindle. The spindle is mounted in big wide bronze bearings in a very solid iron casting, keep them well oiled and bearing and gear noise is not an issue in producing a very fine finish.

The 13" Southbend is by far my first choice for one off work and custom single point threading. It is very precise and repeatable and is a dream to operate and is the last lathe I would consider parting with of the four I presently own. Put an Aloris CXA Mono-block type tool holder system on it and it will do just about anything you can expect of a lathe of that type and do it better than most as long as you are not in a rush...

Happy Shooting,

Mitch & Shadow...

Of all these lathes, the Southbend is the least suited for production work due to its low power and inefficient power transmission method being a flat belt driving the spindle. The spindle is mounted in big wide bronze bearings in a very solid iron casting, keep them well oiled and bearing and gear noise is not an issue in producing a very fine finish.

The 13" Southbend is by far my first choice for one off work and custom single point threading. It is very precise and repeatable and is a dream to operate and is the last lathe I would consider parting with of the four I presently own. Put an Aloris CXA Mono-block type tool holder system on it and it will do just about anything you can expect of a lathe of that type and do it better than most as long as you are not in a rush...

Happy Shooting,

Mitch & Shadow...

R

Roger rodbolt

Guest

I can't help with a price, used iron is everywhere it seems but good iron still demands (and is worth IMHO) a good price. I have a 13" SB with a threaded spindle and two 13" SB's with D1-4 spindles, they look like a larger Heavy 10" but looks don't illustrate the extra weight and rigidity of the 13". A good one is a joy to work and work it will, compared the a smaller SouthBend and similar sized China lathes. The spindle is quite long compared to a 9" or 10" SB. I'll excerpt a from a Tech Article (referencing an older 13") from Live Steam by a lifelong machinest:

"The 13 Inch - This machine is just a 10 Inch machine made large. It has a robust bed and a large headstock leg with the motor mounted in it.The left hand legs are solidly cast and the machine levels right up with ease. The South Bend 13 Inch lathe is heavier in the bed and carriage and tail stock than most modern lathes of comparable swing.Be careful in your comparisons, many lathes are quite heavy because of the gear transmission in their head stocks. weight there does not make a rigid machine, the size and weight have to be in the bed and carriage and tailstock.The 13 Inch strikes the best balance between the tool and instrument lathe and the regular engine lathe. It is sensitive and very easy to manipulate and every bit as accurate as any lathe made. It also is stout and strong and it will not fade in front of large diameter work.This lathe will chase a 1/4-28 thread or a 1 1/2 - 8 with equal ease.Along with its 10 Inch brother it handles large diameter very fine threads so well that they are a joy to cut.For the live steam hobby, this is the lathe for locomotive drivers and large flywheels.These large diameter castings are too delicate for the speed and power of the big gear head lathes and they require a fine finish for appearance. Again this is where the flat belt drive and the plain bearing spindle come into their own."

"The 13 Inch - This machine is just a 10 Inch machine made large. It has a robust bed and a large headstock leg with the motor mounted in it.The left hand legs are solidly cast and the machine levels right up with ease. The South Bend 13 Inch lathe is heavier in the bed and carriage and tail stock than most modern lathes of comparable swing.Be careful in your comparisons, many lathes are quite heavy because of the gear transmission in their head stocks. weight there does not make a rigid machine, the size and weight have to be in the bed and carriage and tailstock.The 13 Inch strikes the best balance between the tool and instrument lathe and the regular engine lathe. It is sensitive and very easy to manipulate and every bit as accurate as any lathe made. It also is stout and strong and it will not fade in front of large diameter work.This lathe will chase a 1/4-28 thread or a 1 1/2 - 8 with equal ease.Along with its 10 Inch brother it handles large diameter very fine threads so well that they are a joy to cut.For the live steam hobby, this is the lathe for locomotive drivers and large flywheels.These large diameter castings are too delicate for the speed and power of the big gear head lathes and they require a fine finish for appearance. Again this is where the flat belt drive and the plain bearing spindle come into their own."

JerrySharrett

Senile Member

I

Of all these lathes, the Southbend is the least suited for production work due to its low power and inefficient power transmission method being a flat belt driving the spindle. The spindle is mounted in big wide bronze bearings in a very solid iron casting, keep them well oiled and bearing and gear noise is not an issue in producing a very fine finish.

The 13" Southbend is by far my first choice for one off work and custom single point threading. It is very precise and repeatable and is a dream to operate Happy Shooting,

Mitch & Shadow...

Notice I said above "not a Clausing for several reasons'.. The sleeve bearings are two of those reasons.

Remember all the posts about "my reamer is chattering". "my chamber has chatter marks,", etc? The heavy sleeve bearings in the spindle is why you will not have this happen with a South Bend.

You can't run them at high RPM (over about 3500) because of the oil-film bearings but they are the smoothest way to spin a workpiece or grinding wheel. Most all cylindrical grinders have sleeve bearings.

For super precision and great finishes they are the best.

S

shot410ga

Guest

That's a nice old lathe. I'd spend a couple of grand to buy it. Does it come with any tooling? If not, better add that in the total cost. It's not cheap.

W

wncchester

Guest

I would kill for a SB in that size and shape with that chuck and steady.

C

chino69

Guest

South Bend

They must not have changed the design for that lathe for decades. When I was in machine shop class in high school in 1967, 68 & 69 our shop had three South Bend lathes that looked identical to the one in the photos. I would only be guessing at when they were manufactured. These machines took alot of abuse but still turned out quality work. Our lathes had little pots on the tailstock that used to hold red lead used to lubricate the center while turning a piece of roundstock. The shop instructor had a big drum of powdered red lead that we would mix with sulphorous threading oil. Back then, powdered lead was not on the hazardous material list, or if it was, we weren't aware of it. At any rate that lathe was a fine piece of equipment.

Lou Baccino

They must not have changed the design for that lathe for decades. When I was in machine shop class in high school in 1967, 68 & 69 our shop had three South Bend lathes that looked identical to the one in the photos. I would only be guessing at when they were manufactured. These machines took alot of abuse but still turned out quality work. Our lathes had little pots on the tailstock that used to hold red lead used to lubricate the center while turning a piece of roundstock. The shop instructor had a big drum of powdered red lead that we would mix with sulphorous threading oil. Back then, powdered lead was not on the hazardous material list, or if it was, we weren't aware of it. At any rate that lathe was a fine piece of equipment.

Lou Baccino

I wish it had was a little slower speed for threading, .

I had a 16" SB and it had the back gears. I can't imagine needing slower speeds than what that lathe had.

Do you know how long the spindle is ffom the face of chuck jaws to the rear of the spindle? it doesn't appear to be over 20" from the picture.

It's right around 20". Comes with more tooling and a 4 jaw chuck also.

Fella wants $4000 for it. Come out of a prototype lab for one offs.

It's mint, I'm going to look at it next week and run a test bar on it.

Pete Wass

Well-known member

Guess I would pass

There is no doubt it looks great and probably is but if I were going to do barrel work I would want one with a shorter spindle and the flat belt is a PITA. I have a 10" Toolroom SB and although it is a nice machine I would prefer to have a machine with more modern features, particularly something other than the flat belt.

There is no doubt it looks great and probably is but if I were going to do barrel work I would want one with a shorter spindle and the flat belt is a PITA. I have a 10" Toolroom SB and although it is a nice machine I would prefer to have a machine with more modern features, particularly something other than the flat belt.

Last edited:

colchester

Member

I think they are asking full price plus. Very nice machine and if your in love with it and it fits your needs its ok. I would think you could find a better deal , esp.in your area of the country. I dont know how much you have hunted around yet, I will conceed you probably wont find a nicer one and the time youll spend looking is worth something.

There are 3 SB 13" lathes at Vander Ziel Machinery,(Michigan) see the link below..They are a whole lot less in price. $1750

http://www.vanderzielmachinery.com/index1.php?cPath=31

Rick

http://www.vanderzielmachinery.com/index1.php?cPath=31

Rick

JerrySharrett

Senile Member

The one pictured on that site is really rough though.There are 3 SB 13" lathes at Vander Ziel Machinery,(Michigan) see the link below..They are a whole lot less in price. $1750

http://www.vanderzielmachinery.com/index1.php?cPath=31

Rick

Yup Jerry,

it looks a little rough, I agree with that but that doesn’t mean that it is a bad machine. I worked with machines for 30+ years that had War Machine name plates on them, run them, repaired them, set them up and they looked rough but they were some of the best and most reliable machines we had. When I left in 1997 they were still in service, hard to find those good old machines, just wish I had one of those Parker Majestic I used. I just purchased this mill, looks a little rough but everything is tight, intact and works, as for how well ?, we will just have to find out but for the price I can’t gripe. (It is a 1951 all original even the vise is an original Bridgeport, could have a better one though)

Rick

it looks a little rough, I agree with that but that doesn’t mean that it is a bad machine. I worked with machines for 30+ years that had War Machine name plates on them, run them, repaired them, set them up and they looked rough but they were some of the best and most reliable machines we had. When I left in 1997 they were still in service, hard to find those good old machines, just wish I had one of those Parker Majestic I used. I just purchased this mill, looks a little rough but everything is tight, intact and works, as for how well ?, we will just have to find out but for the price I can’t gripe. (It is a 1951 all original even the vise is an original Bridgeport, could have a better one though)

Rick

Attachments

JerrySharrett

Senile Member

Yep, those little brass plates that read "Approved for production by the War Production Board". I've seen several. We may have to use them again. We sure do not have any machine tool producers in this country now, thanks to our letting subversives take over!!!Yup Jerry,

it looks a little rough, I agree with that but that doesn’t mean that it is a bad machine. I worked with machines for 30+ years that had War Machine name plates on them,

Rick