Bill Calfee: I will certainly try to get a copy of your article. Which month of Precision Shooting do you expect to see it in? I don't subscribe, but I will try to look it up.

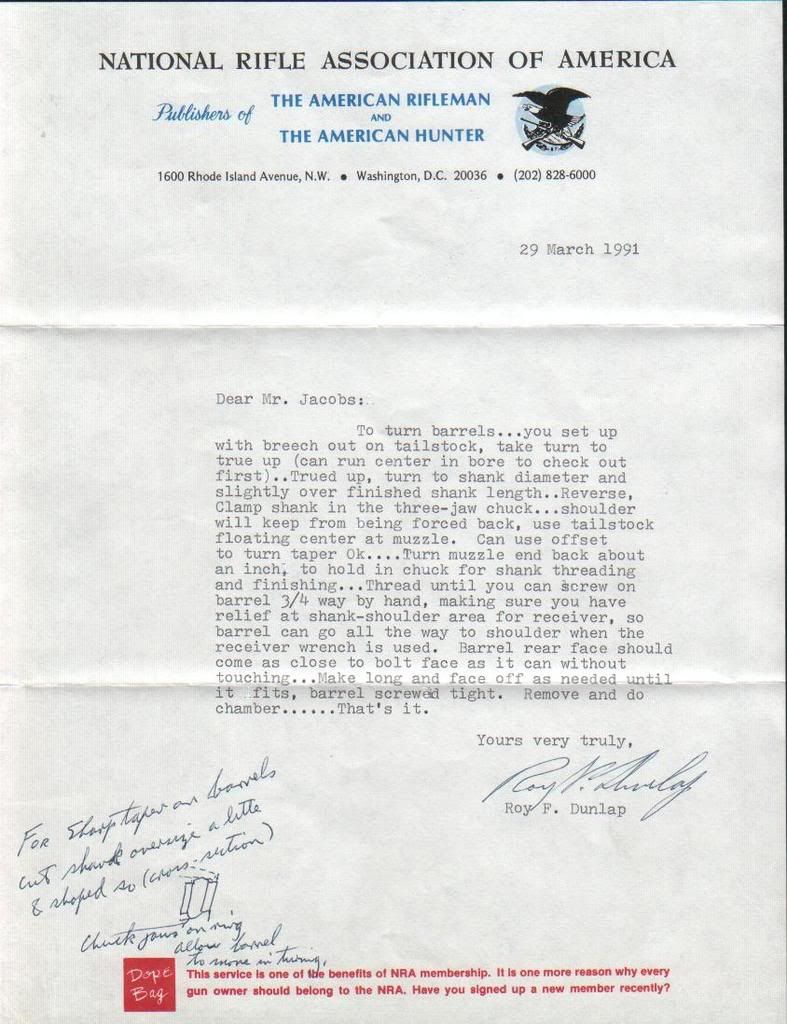

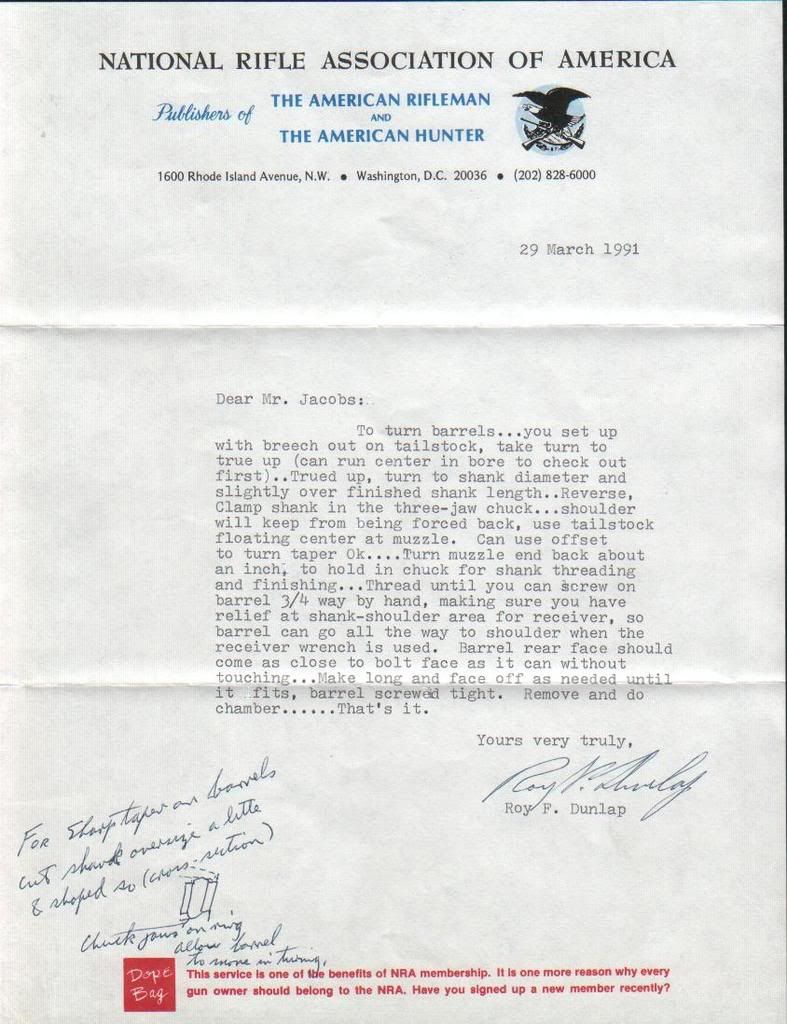

Others: What you are missing is the letter that I sent to the Dope Bag. Unfortunately, I don't have it either. As I recall, I was wanting to make a barrel for an L461 Sako action. There were no commercial tapers that would work for the little gun, so I wanted to start with a blank. I asked, as I recall, if I could do the taper by offsetting the tailstock, and whether it was better to cut toward the breech or toward the muzzle.

I enjoy reading this forum even though I am not a benchrest shooter (or smith). I make primarily hunting rifles, and I chamber in the (shudder) steady rest. At the time Mr. Dunlap wrote his book, I doubt that many gunsmiths had access to the kinds of equipment that we see today. I can recall a lot of Atlas lathes in garages turning out barrel work on Mausers. Many of those fellows didn't even have a 4-jaw chuck.

I never actually tried the method that Mr. Dunlap suggested, turning a "ring" on the tennon and letting it "float" in the three-jaw chuck, presumably driven by a dog. I have no doubt that it could be done that way, however. Nowadays I have a 13x40 lathe with a taper attachment, and if I need to reduce the size of a barrel, I set it up between centers, or occasionally in a 5C collet, and turn it down using that taper attachment. Once I finally got that tailstock dialed in, I didn't want to mess with offsetting it!

The letter is a piece of nostalgia, and I enjoy looking at it whenever I refer to the book, which is pretty darned often, come to think of it.........

Clemson