Hi, Kory. HJere's the method I use to establish the 'zero' or 'just touching' point:

-Remove firing pin. assy from bolt.

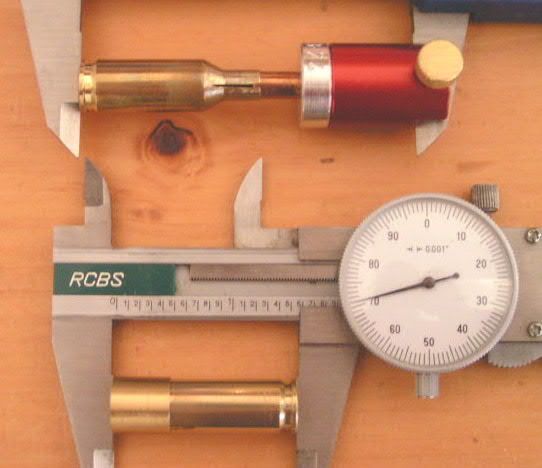

-Full length size a case that's been fired in your chamber. If you are using a bushing die, use a bushing that's .003-.004 under loaded round measures. You want a good amount of neck tension for this process.

-Seat the bullet 'way long.

-Polish the bullet with some 0000 steel wool.

-Make sure the chamber/barrel are clean and dry. Lube the locking lugs.

-Chamber your dummy round. It will close hard, as the long seated bullet meets the rifling.

-Open the bolt and remove the round. If the bullet stays in the bore, just tap it out with a cleaning rod or wooden dowel.

-Examine the bullet and you'll see the marks from the rifling. If the bullet stayed in the bore, just resize the case, reseat it and repolish with 0000.

-Seat the bullet deeper by .010 and repeat. You'll see the marks starting to fade as you move the bullet further into the neck each time you change the seating depth. When the marks start to get noticably lighter, change the seating depth change to .005, as you're getting closer to 'zero'.

-When the marks just disappear, you're at the 'zero' or 'just touching' point for

that bullet.

Record the seating stem length or base-to-ogive dimension and record that. Repeat for each bullet you're going to use.

Once you've done it a time or two, it will take you about 5 minutes to find your 'zero' with any new bullet.

Hope this helps.

-Al