)Stephan

Member

Dear boys & girls,

For this being my first post in this Forum I will shortly introduce myself.

I've been shooting for about 10 years now, taking part in several national and smaller matches in germany.

Shooting keeps to be my favourite sport after many years and one could say I'm quite interested in Benchrest and other accuracy-dominant disciplines.

Proudly owning a BR50 rimfire gun I quite often participate in Matches and love it like nothing else.

Now this topic will be related to centerfire rifles, in my case a trued Rem700 Action with a .338 neck--chambered Shilen Barrel cal.308Win, McMillan Fiberglass Stock and Nightforce NF 42x optics.

Although I believe to run into the same problems with my other guns, I'd probably say this is my most accurate one.

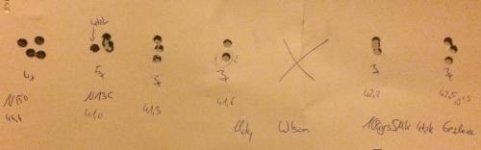

So now to describe my observations in short terms, my group sizes from ladder testing tend to be very inconsistent. E.G. My best load from the last week will often not be the best group from the actual week.

Let's say it's just +/- 0.3grs of powder.

I have observed this for quite some time (some years maybe?) and feel quite frustraded as you can imagine. Well of course I read a lot of literature and Forums regarding probably every accuracy-related topic yet, but nothing seemed to eliminate the cause up till now.

So for example, taking into consideration Tony Boyers book and several other BR or long range related books i tried all of the following:

Neckturning, Bushing Dies, individual charge trickling, shooting in the same temperature, all kind of barrel cleaning methods, several powders/bullets/primers/cases, ... I don't know what to check next.

I have also tried several scales for powder charges, but nothing really helped.

What I can say is that bullet concentricity etc. is minimal and also I try to keep all other tolerances the same (currently shooting Lapua brass).

But what annoys me the most is, that the difference from charge weight is really minimal from one week to the other..

Have you ever encountered something alike?

And can you give any advice?

Cheers,

Stephan

P.S. I'm FL resizing my cases with a .335 Bushing and use a Wilson seater.

Also i set back the shoulder by ~.002 and the bullets are touching the lands (they are not pushed back in the case while closing the bolt, but have uniform touch-markings).

In addition to that I tried moly (self coated) and non moly.

Additionally I tried neck sizing and many different dies..

For this being my first post in this Forum I will shortly introduce myself.

I've been shooting for about 10 years now, taking part in several national and smaller matches in germany.

Shooting keeps to be my favourite sport after many years and one could say I'm quite interested in Benchrest and other accuracy-dominant disciplines.

Proudly owning a BR50 rimfire gun I quite often participate in Matches and love it like nothing else.

Now this topic will be related to centerfire rifles, in my case a trued Rem700 Action with a .338 neck--chambered Shilen Barrel cal.308Win, McMillan Fiberglass Stock and Nightforce NF 42x optics.

Although I believe to run into the same problems with my other guns, I'd probably say this is my most accurate one.

So now to describe my observations in short terms, my group sizes from ladder testing tend to be very inconsistent. E.G. My best load from the last week will often not be the best group from the actual week.

Let's say it's just +/- 0.3grs of powder.

I have observed this for quite some time (some years maybe?) and feel quite frustraded as you can imagine. Well of course I read a lot of literature and Forums regarding probably every accuracy-related topic yet, but nothing seemed to eliminate the cause up till now.

So for example, taking into consideration Tony Boyers book and several other BR or long range related books i tried all of the following:

Neckturning, Bushing Dies, individual charge trickling, shooting in the same temperature, all kind of barrel cleaning methods, several powders/bullets/primers/cases, ... I don't know what to check next.

I have also tried several scales for powder charges, but nothing really helped.

What I can say is that bullet concentricity etc. is minimal and also I try to keep all other tolerances the same (currently shooting Lapua brass).

But what annoys me the most is, that the difference from charge weight is really minimal from one week to the other..

Have you ever encountered something alike?

And can you give any advice?

Cheers,

Stephan

P.S. I'm FL resizing my cases with a .335 Bushing and use a Wilson seater.

Also i set back the shoulder by ~.002 and the bullets are touching the lands (they are not pushed back in the case while closing the bolt, but have uniform touch-markings).

In addition to that I tried moly (self coated) and non moly.

Additionally I tried neck sizing and many different dies..

Last edited: