Kyle Schultz

Member

My 30BR chamber has a 0.330" neck. My brass was initially neck turned to +/- 0.0096". My loaded rounds (BIB 112gr) measure +/- 0.328” so I have about 0.002" of clearance. While the gun is shooting fine, I've wondered about skimming the necks a 2nd time down to 0.0091" and thereby increase the clearance up to 0.003”.

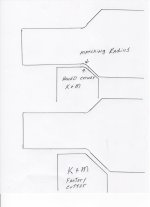

I use K&M tools. My .30cal expander measures 0.3086" while the pilot measures 0.3074". My fired cases fit loose on the expander which makes sense since theoretically a fired case would have an neck ID of 0.3108". My Harrell's resizing die only sizes the upper half of the neck. That's fine for normal reloading but in a situation where I need to reduce the entire neck length down prior to expanding out for neck turning, that won't work. K&M sells larger expander and pilot mandrels. 0.311” and 0.32” are the next sizes up. My hesitation relates to what happens after I neck back down after reszing. The bottom portion of the case neck will be oversized compared to the chamber neck.

Will that cause chambering issues? Is there a better procedure for turning the necks down to 0.0091”? Thanks

I use K&M tools. My .30cal expander measures 0.3086" while the pilot measures 0.3074". My fired cases fit loose on the expander which makes sense since theoretically a fired case would have an neck ID of 0.3108". My Harrell's resizing die only sizes the upper half of the neck. That's fine for normal reloading but in a situation where I need to reduce the entire neck length down prior to expanding out for neck turning, that won't work. K&M sells larger expander and pilot mandrels. 0.311” and 0.32” are the next sizes up. My hesitation relates to what happens after I neck back down after reszing. The bottom portion of the case neck will be oversized compared to the chamber neck.

Will that cause chambering issues? Is there a better procedure for turning the necks down to 0.0091”? Thanks